Oznaczenie: LPG 10 ( BUTAPAL 10 ) pomarańczowe pierścienie co 2,5 metra. Ciągłe, odporne na ścieranie wytłoczenia norm : ELAFLEX LPG 32 · EN 1762 D · Ω · FLÜSSIGGAS · L.P.GAS · TEMPERATUR - 40° C + 70° C · DVGW – DG-4621 AU 0049 · M · 25 BAR / 350 PSI · · ContiTech · MADE IN GERMANY · 3Q-17

LPG to wytrzymały, trwały z mało rozciągliwymi oplotami wąż tłoczny zaprojektowany do masowych przeładunków LPG, oraz gazu ziemnego.

Może być przyłączany do pomp, w celu tankowania pojazdów, oraz do załadunku i rozładunku cystern kolejowych, drogowych, czy tankowców.

Dzięki możliwości zwijania go na bęben, może być również stosowany w cysternach przy dostawach do domowych i przemysłowych zbiorników magazynowych.

Możliwe stosowanie z propenem (propylenem) – wymagane jest nakłucie.

Nie nadaje się do transferu amoniaku. Zatwierdzony przez Niemiecki Związek Branży Gazowej i Wodnej (DVGW), homologacja Nr DG-4621 AU 0049;

LPG

- Warstwa wewnętrzna: NBR, czarna, przewodząca, odporna na dyfuzję;

- Wzmocnienia: oploty tekstylne z dwoma skrzyżowanymi cynowanymi żyłami miedzianymi;

- Warstwa zewnętrzna: chloropren (CR), czarny, przewodzący prąd elektryczny, odporny na płomienie, ścieranie, ozon, UV i starzenie;

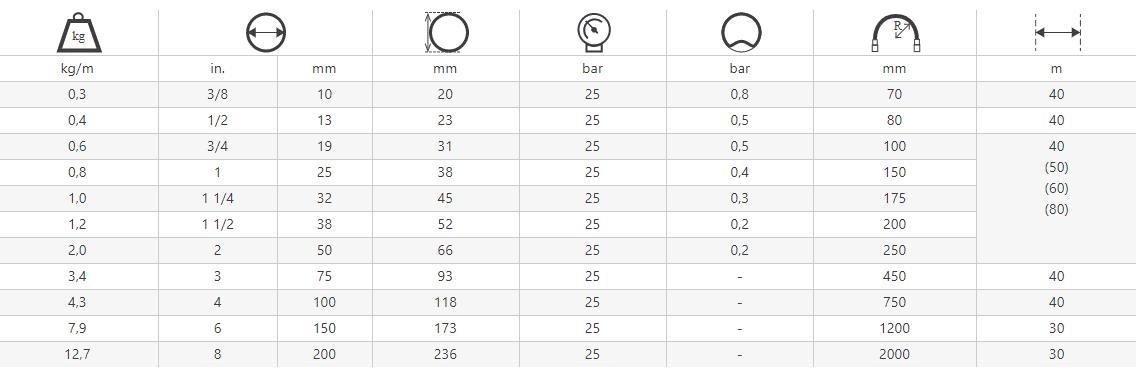

- Ciśnienie: robocze 25 bar, testowane 40 bar;

- Temperatura pracy: – 40° C do + 70° C ( Wąż typu LPG-LT nie pęka do – 50° C );

- Przewodność elektryczna: zgodnie z normą EN 1762 jest to wąż typu „Ω” o rezystancji R<106 mierzonej między końcami przewodu, bez podłączania miedzianych przewodów do końcówek, lub typu „M” z R<102 w przypadku podłączenia linek do złącza;

Na żądanie klienta dostępna jest wersja ssąco/tłoczna LPG S ze stalową spiralą.